Page 1 of 2

opps

Posted: Fri Jul 24, 2009 7:37 am

by 4dawgma

Ok here's my problem. I was leaking gear oil from the rear axle on a 97 or 98 honda foreman. Put in a new seal and might as well throw in a new bearing while I'm there right

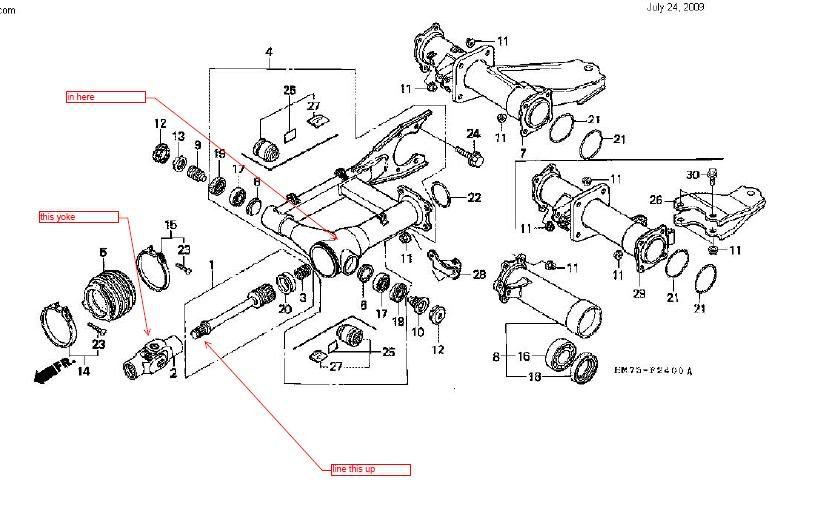

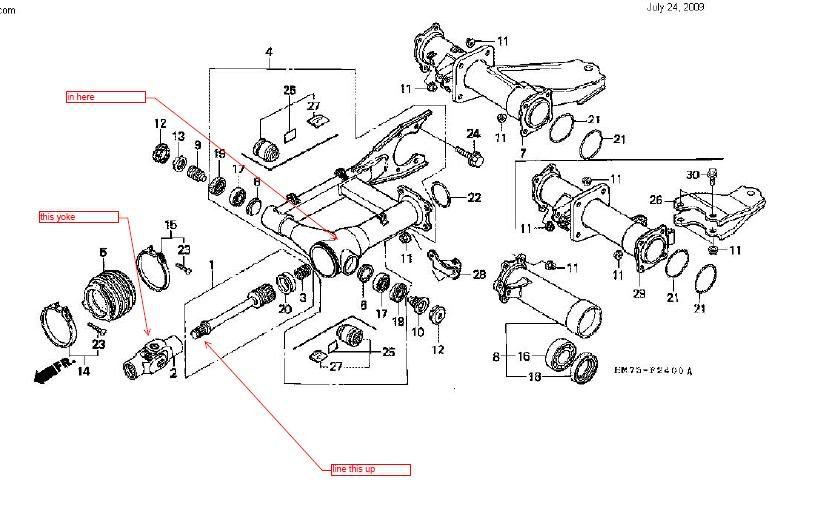

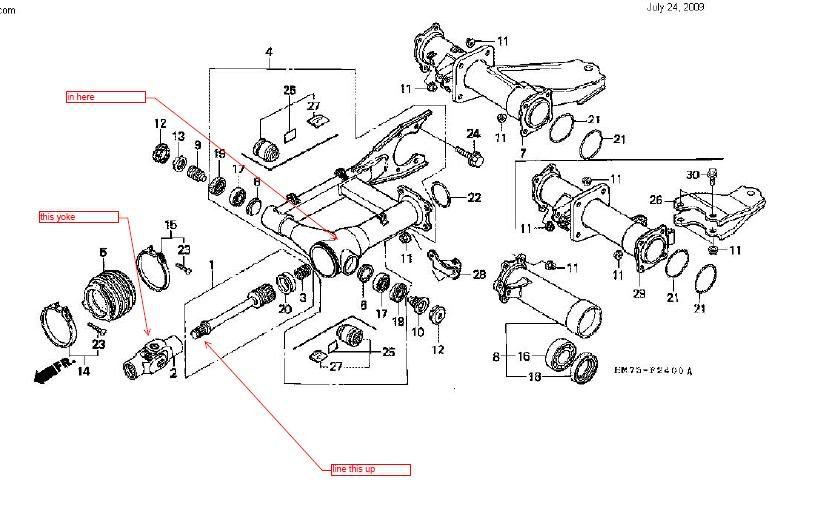

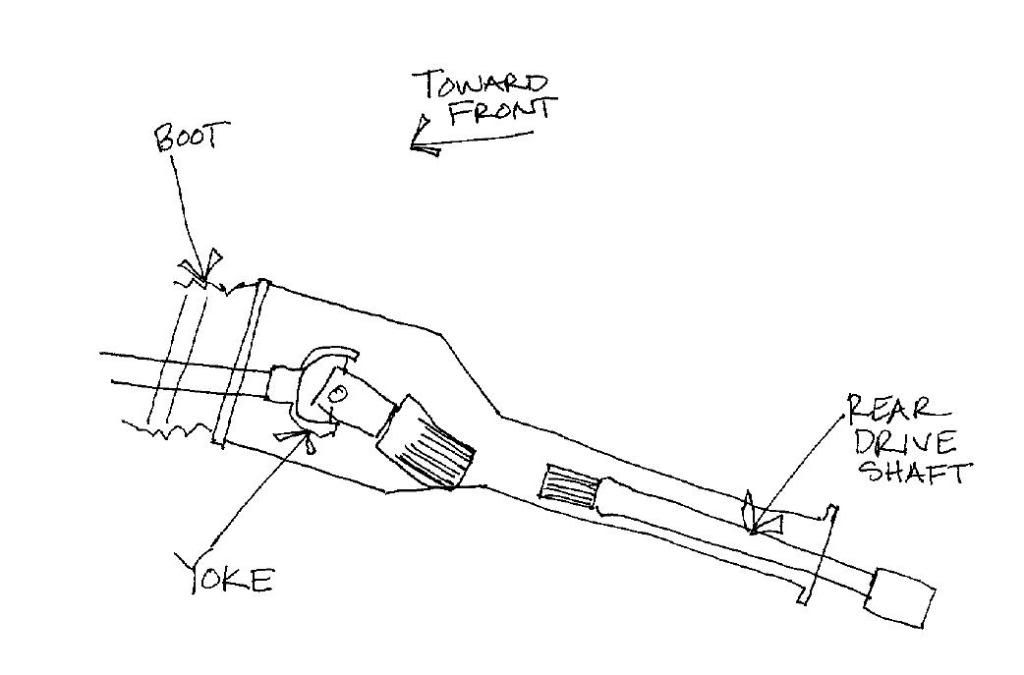

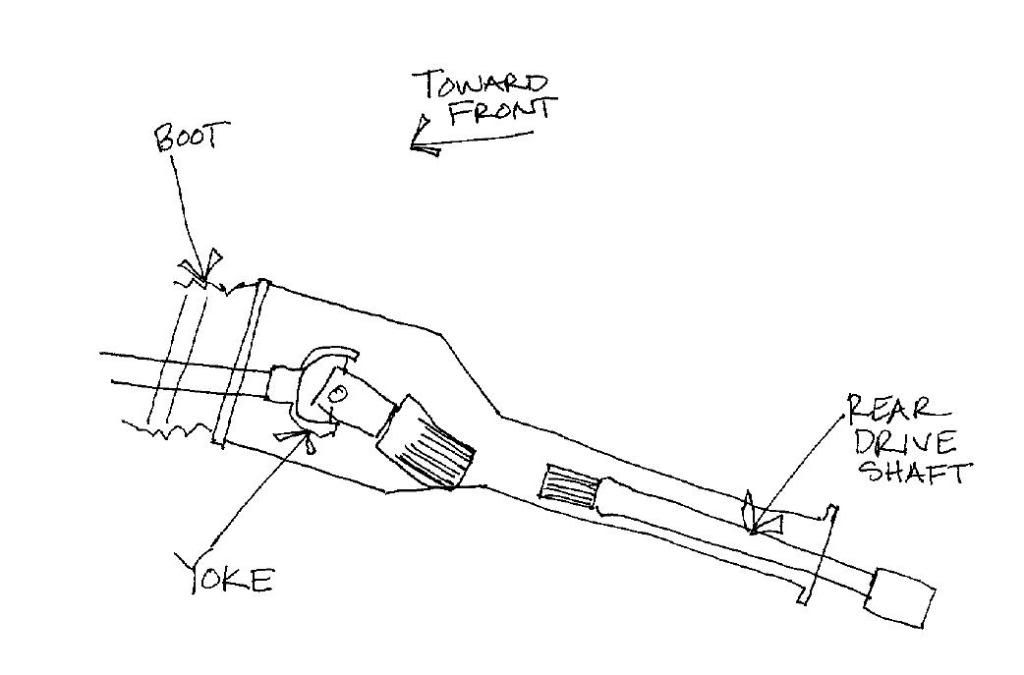

not so hard. well in turn into a pretty good project but I managed to get every thing back together. So I'm putting things back together yesterday and ran into a little problem. I was trying to reinstall the gearbox thingy. first thing you have to do is slide the drive shaft into this little tube and aline the splines with the yoke. but my problem is the yoke is pointed down and I can't get splines lined up. anybody know of a trick for this with taking off more stuff? I wish I knew how to get pictures of my phone so I could show ya'll what I'm up against.

Re: opps

Posted: Fri Jul 24, 2009 7:39 am

by 4dawgma

Oh yeah one more thing.... I'm coming in from where that O-ring labeled 22 is

Re: opps

Posted: Fri Jul 24, 2009 7:43 am

by donia

can you roll it enough to get the yoke to turn almost a quarter turn so the end isn't straight down - so that the yoke is half cocked?

or can you pull the boot (#5) back or is there room to get in there?

Re: opps

Posted: Fri Jul 24, 2009 7:58 am

by 4dawgma

the yoke is inside that tube where it gets larger. and the tube pivots (attached to frame) at #12. I'm trying to figure out a way to do without taking all that off. you can pull the boot back but it's actually well before the yoke.

Re: opps

Posted: Fri Jul 24, 2009 8:14 am

by donia

4dawgma wrote:the yoke is inside that tube where it gets larger. and the tube pivots (attached to frame) at #12. I'm trying to figure out a way to do without taking all that off. you can pull the boot back but it's actually well before the yoke.

does the yoke fit with some wiggle room? if so you MAY can pull the boot back and use a long screw driver or flat piece of steel to slide under the yoke to prop up the side you are trying to line splines up with.

Re: opps

Posted: Fri Jul 24, 2009 8:16 am

by DEERHUNT

Check the splines for trash and grease build up. If the yoke is still in the tube use a stiff brass cleaning brush from a gun cleaning kit. If you can turn the yoke, have someone hold the drive shaft in the tube pushing just a little while you turn the yoke.

Re: opps

Posted: Fri Jul 24, 2009 8:20 am

by dukmisr2005

there is room to slide the boot back but be careful and don't crack it.. i did the same to mine but i didn't remove the shaft when i pulled the gear box.. i installed a new gear box, axel, seals, and bearings.. and greased all splines when reassembling..

Re: opps

Posted: Fri Jul 24, 2009 8:35 am

by 4dawgma

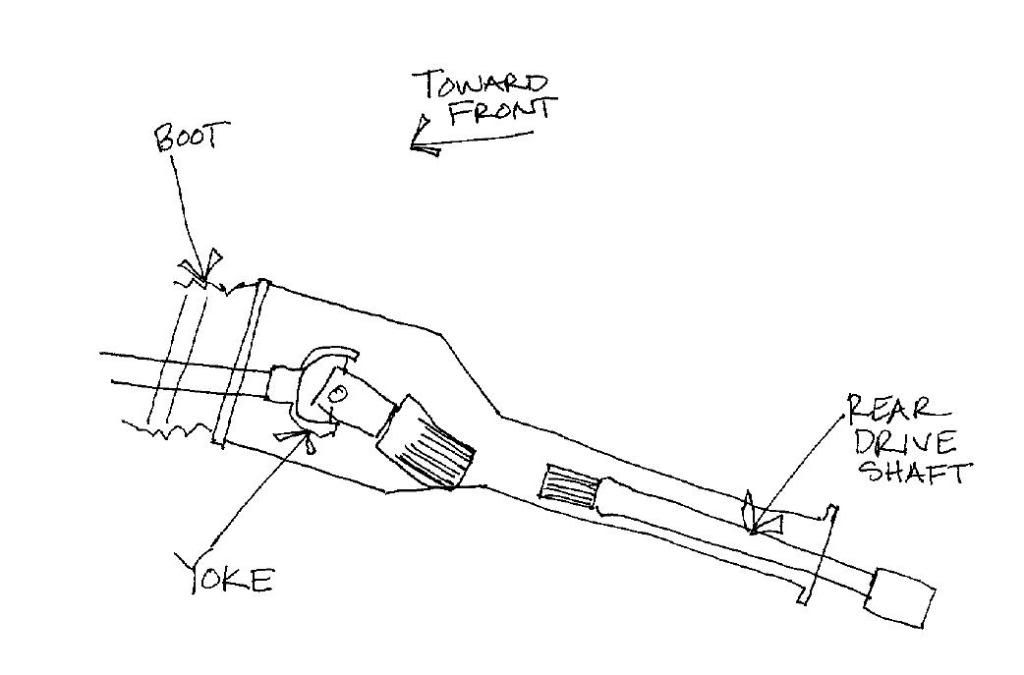

this may help some, I need some way to lift that yoke but when shaft is all the way in it "seals" that tube making it difficult to remove third hand

Re: opps

Posted: Fri Jul 24, 2009 8:46 am

by donia

4dawgma wrote:this may help some, I need some way to lift that yoke but when shaft is all the way in it "seals" that tube making it difficult to remove third hand

winch it up a rafter, then the yoke will be hanging straight down....that should add a new element of ingenuity (& pucker) to the ordeal - ingenutity of getting the part to act right and the pucker of hoping the rafter holds while you are under the wheelie trying to put the shaft in and bolt it up.....only joking - don't wanna come out and see legs sticking out from under it where it fell on you!!

Drill

Posted: Fri Jul 24, 2009 8:46 am

by jdbuckshot

Drill a small hole in the housing above the yoke, use a magnet to pull it up and stick the drive shaft in, fill the hole with a Grease zert or bolt.

Or drill the hole in the bottem of the housing and push it up with a rod, then fill the hole with a grease zert or bolt

JD

Re: opps

Posted: Fri Jul 24, 2009 8:50 am

by donia

4dawgma wrote:I need some way to lift that yoke but when shaft is all the way in it "seals" that tube making it difficult to remove third hand

will a thin piece of metal fit in from where the boot is (like a slim jim car unlocker)? there has to be some room for the u-joint/yoke to spin and flex inside the tube.

Re: opps

Posted: Fri Jul 24, 2009 9:11 am

by 4dawgma

maybe. gonna probably throw everything thing I got at it this weekend before I forget where all these nuts and bolts go

all ideas are appreciated. I like your winch idea

way to think outside the box

Re: opps

Posted: Fri Jul 24, 2009 9:27 am

by donia

4dawgma wrote:maybe. gonna probably throw everything thing I got at it this weekend before I forget where all these nuts and bolts go

all ideas are appreciated. I like your winch idea

way to think outside the box

if the wife doesn't have me working on honey-do's this weekend, i'll run out and see if i can assist - if nothing else i can open a fresh beer for you and console you when you get to cussin' too bad or get you a bandaid when you skin a knuckle!!

may be in the morning before i can get out.

Re: opps

Posted: Fri Jul 24, 2009 10:50 am

by cwink

I would think you could you turn the wheeler on it side.. That way the yoke should line up. I can't see the pic, so I am assuming that the yoke is inside the rear end housing and your trying to stab the axel into the yoke.

Re: opps

Posted: Fri Jul 24, 2009 10:54 am

by 4dawgma

so I am assuming that the yoke is inside the rear end housing and your trying to stab the axel into the yoke.

sounds kinda kinky, I'll try it but not sure the wife's gonna like it

not so hard. well in turn into a pretty good project but I managed to get every thing back together. So I'm putting things back together yesterday and ran into a little problem. I was trying to reinstall the gearbox thingy. first thing you have to do is slide the drive shaft into this little tube and aline the splines with the yoke. but my problem is the yoke is pointed down and I can't get splines lined up. anybody know of a trick for this with taking off more stuff? I wish I knew how to get pictures of my phone so I could show ya'll what I'm up against.

not so hard. well in turn into a pretty good project but I managed to get every thing back together. So I'm putting things back together yesterday and ran into a little problem. I was trying to reinstall the gearbox thingy. first thing you have to do is slide the drive shaft into this little tube and aline the splines with the yoke. but my problem is the yoke is pointed down and I can't get splines lined up. anybody know of a trick for this with taking off more stuff? I wish I knew how to get pictures of my phone so I could show ya'll what I'm up against.